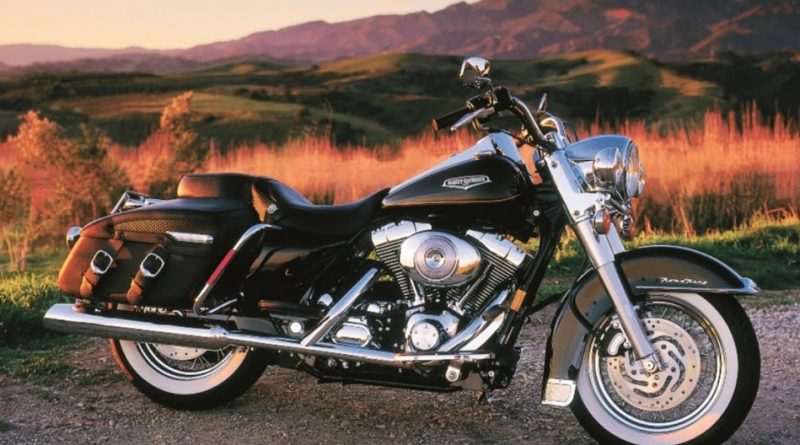

The Harley-Davidson Twin Cam: Bigger, Bolder and Better?

With no competition, we’d all be riding Evo’s. Discover how the Motor Co. responded to their competitor’s challenge with the Harley-Davidson Twin Cam.

Years in Production: 1999 – 2016

Engine Size: 88ci -103ci

Horse Power: 62hp – 74hp

What’s the Big Deal? the most versatile engine Harley-Davidson have ever produced

Famous Harley-Davidson Twin Cam Riders: Paul Troxner, T.R Reiser, Brett Ray

Tell me something Weird about the Twin Cam: motorcycle racer, Brett Ray strapped a propeller to his TC96 engine and used it to power a light aircraft.

Most new engines throughout Harley-Davidson’s timeline have come about due to the need to stay ahead of the competition. By the time the Evolution made its appearance, though, environmental regulations concerning noise and exhaust emissions added a whole new dimension to the mix.

If the Evo had it tough, then the number of environmental riders on Harley’s next step-up the evolutionary ladder meant that H-D had to leap in a new direction.

Several other factors also played a role in the Twin Cam’s development. These came from inside the H-D factory as well as out. As great as the Evo engine was compared to the Shovel, warranty claims for bad crankcases cost the factory dearly. The financial hit was bad enough, but sliding down the reliability slope had to be avoided at all costs.

Attack of the Harley Clones

Another contributing factor was the blossoming aftermarket industry. Unfettered by the rules and regulations concerning vehicle manufacturers, tuning specialists all over the US made hop-up parts and complete look-alike engines with larger bores and more power. Harley was losing out.

Harley owners were turning more and more to third-party tuning parts. In 1992, eight years into the Evo’s production run, the bods in the H-D marketing department highlighted the need for a new, much more powerful engine.

“Competition is always a good thing. It forces us to do our best. A monopoly renders people complacent and satisfied with mediocrity.”

– Nancy Pearcey

Ideas once deemed either too costly or too complex to consider as amendments to the Evo engine, were now an option for an entirely new power plant. A clean sheet would also allow H-D to address the Evo’s shortfalls. As a result, designers began work on a new project, code-named P-22.

Exhaust emissions could be taken care of with catalytic converters and electronic fuel injection. However, they soaked up power like a sponge. In addition, the noise emitted from the Evo’s famous cam whine had also to be dealt with.

The answer was a radical re-design. Upping the engine’s size to 1450cc would take care of the extra power, and a change to twin cams would reduce the noise by half.

Harley’s P-22 Breaks Cover

Although the Twin Cam shared only 18 parts with the Evolution engine, as with all new engines, something of its predecessor remained. While the bottom end was all new, the prototype Twin Cam engine fired up one year after the project began, and had what was basically Evolution heads.

Related: How to clean, condition and care for leather saddlebags

While they were similar in appearance, inside the combustion chamber was a whole new story. The Evo’s famous D-shaped chambers were now replaced with a bathtub shape. This oval combustion chamber allowed for better detonation, raised compression ratio and had a greater tolerance to low-quality gas.

Before the release of the Evolution in 1894, H-D undertook its most rigorous series of bench testing. The factory put the new engine through thousands of hours on the test rig, and for the Twin Cam, this was no different.

On paper, the new power plant looked to have all the bases covered. However, under test conditions, the engine leaked oil out of every surface with a gasket.

The problem of returning oil and crankcase pressure drove Harley engineers to distraction. This issue led to them bringing in a young research engineer called Paul Troxner to consult.

Twin Cam Engine Developments

The test process was laborious and time-consuming, delaying the launch by a year, but Troxler eventually delivered the goods.

Between June 1998 and July 2001, the research engineer filed no less than six patents with H-D as the assignee. These patents covered everything from engine breathers and dry-sump cooling systems to a dividing wall between the sump and cam chest to prevent oil drain.

With oil routing sorted, an interesting inter-departmental wrangle began between design and marketing. Marketing made a case for a new engine with more power. Engineers pointed out that more power meant more heat and would mean an oil cooler was required.

Marketing responded by saying that an oil cooler would mess with the engine’s classic lines and make their job harder. The compromise would eventually mean a complete redesign of the head to encompass 50% larger cooling fins. This expensive alternative to the oil coolers cheap modification, confirms that for H-D, form will often win over function.

Not wanting to be caught napping again in the power stakes, one of the most significant improvements to the new engine was that the design allowed future power upgrades.

Take a listen: all the Harley-Davidson engine sounds throughout time

First Generation Twin Cam

It’s clear from this addition that Harley had intentions of increasing the TC’s size and power output in the not too distant future. What they didn’t want was to delay the launch any further.

While engineers battled with adding counterbalance measures to the new engine, Harley went ahead in 1999 and launched the Twin Cam. Hence, why the first generation TC88’s are all rubber mounted models.

The Twin Cam 88B (B for balancer) rigidly mounted in the Softail range, appeared one year later. The bike they chose to lead the charge, the Softail Deuce, was a strange selection, looking like it slipped through on one of Willie G’s off-days.

With its odd-shaped tank, 21-ins front wheel on spindly forks, and a roulette wheel solid rear with lopped off fender, the Deuce had parts-bin special written all over it. Thankfully, one of a 24-bike line-up, the Softail Heritage Classic overshadowed its presence. The FLSTC first made its appearance in 1986 and remains a best seller to this day.

The 88B Heritage had big shoes to fill, and it didn’t disappoint. Thanks to the Motor Co’s marketing department sticking to their guns, the new bike looked almost identical. The changes, however, added up to an entirely different machine.

Second Generation Twin Cam

To begin with, the second-generation engine was fitted with twin balancers, which made an incredible difference. The 1450cc engine produced an extra six horsepower on its own, not a staggering increase. Yet the real story was the difference in torque.

The Evo pushed out around 69-ft∙lbs at 3000-rpm, while the Twin Cam showed a significant increase of 84-ft∙lbs at 3500-rpm. Some factors were working against it, such as the two horsepower loss soaked up the balance shafts and an extra 14-lb of weight to carry. These, though, were small potatoes.

Related: How to maintain your motorcycle chain

Together with a slightly shorter stroke and higher compression, the increase in torque was even more noticeable due to the 88B’s ability to rev faster.

With a 30-percent stiffer frame and a 90-percent reduction in engine vibration, the Heritage, along with the rest of the 2000 Softail range, was a revelation, exceeding all expectations.

Ironically, the bike’s lack of vibration caused problems. Without the usual amount of friction generated by vibration, the gearbox’s shifting mechanism slipped into a false neutral between gearshifts.

The new gearbox was so slick riders would have had to change their engineer’s boots for slippers. Not something ever likely to happen, so extra tension was added to the spring mechanism.

Harley’s Six Million Shift Gearbox

The original gearbox and testing of the new modification saw Harley engineers putting the gearbox through almost six million shifts. According to Harley- Davidson, the Twin Cam engine was one of the biggest development programs in H-D history. Judging by the test program stats, they weren’t joking.

According to Harley tuning expert Donny Petersen, the first three years of Twin Cam production produced the best engines. These Twin Cams with Timkin bearings on the sprocket shaft have the potential to last more than 500,000 miles.

The Motor Co’s over-engineering also extended to their Teflon coated hypereutectic aluminum pistons. Matched together with cylinder liners thick enough to stand five re-bores, and you’ve got one exceptionally tough engine.

Hypereutectic explained:

A hypereutectic piston is a piston cast from a special aluminum alloy that allows for larger amounts of silicone to be added. This gives a much stronger but lighter piston.

The Twin Cam Tensioner Problems

With things going so well, it’s almost a shame to throw a spanner in the works. However, that came in the shape of the cam, chain tensioner. As the name suggests, two cams were used instead of the Evo’s single-cam, driven by a single row chain with a spring-operated friction tensioner.

Related: TOP-10 Retro Motorcycle Helmets

Related: TOP-10 Retro Motorcycle Gloves

Unfortunately, the tensioner shoe was made of plastic and the spring too aggressive, meaning failure reported in as little as 15,000 miles or less. The tensioner problem seems to be the sole fail on what is otherwise a more or less bulletproof engine.

Not surprising but still annoying, H-D sold Screaming Eagle upgrades to deal with the problem they’d created, and aftermarket part manufacturers had a field day. The more popular of which offered a gear-driven alternative to eliminate the cam chain and its self-destructing tensioner.

Therein lays another problem. In 2003, H-D changed the Timken bearings for a plain roller bearing on the crankshaft. The reason for this was to speed up engine assembly time. The change in bearings allowed for more float in the crank, meaning gear-driven cams weren’t an option.

Regardless, the cam chain tensioner issue occupied more space in Twin Cam forums than the cost of gas debate. All of which in 2007 resulted in H-D modifying the part with a hydraulic actuated tensioner.

As it turned out, 2007 was a big year for other reasons too. Emission laws cranked up another notch forcing H-D to adopt electronic fuel injection on all Twin Cam models.

Larger Capacity Twin Cam

This year also saw the TC96A (rubber mount engines), and TC96B (Softail models) hit the showroom floor. Taking advantage of the engine’s built-in expansion potential; the 96’s bigger displacement saw a torque increase of around 8-percent

When chugging through bumper-to-bumper traffic, the power increase also brought with it overheating problems for the bagger range. The factory addressed this problem with EITMS (Engine Idle Temperature Management System).

This feature allowed fuel to be injected into the combustion chamber but cut the ignition to the rear cylinder. Your big bad bagger was thus turned into a lumpy single-cylinder engine.

Harley owners, always on the lookout for a naming ceremony, christened it ‘Parade Mode.’ At the time, launched as a retro-fit for 2008 models, by the following year, all Twin Cam, touring models, featured this as standard.

Twin Cam gets Parade Mode

Riders could now manually switch the lumpy gravy feature on and off by manipulating the cruise control feature. H-D tech bodies altered the name to RARCCO (Rider Activated Rear Cylinder Cut Out). A name capable of knocking Yamaha’s (Chip Controlled Throttle System) off the top slot for the longest acronym.

Trick throttles aside, the entire bagger range got a significant update that year. Updates included a new frame, swinging arm, engine mounts, bigger tank, new exhaust system brakes and, fairing. All of which created an excellent diversion for Willie G to slip the Rocker C into the line-up.

I can understand why he did this. After all, America was crammed with boutique V-Twin chopper builders all living off the Harley bandwagon. Still, if Willie G thought he was firing a shot across their bows, it was more like he’d shot himself in the foot.

On paper, the Rocker C had all the right components, fatback, kicked-out skinny front, stretched tank, single-seat, trick pillion, etc. For me, as a motorcycle journalist and Harley owner, invited to its launch, my heart sank.

Short Reign of the H-D Rocker C

All I saw was a bike whose form had so far exceeded its function as to be a caricature of the awesome, soul-stirring bikes that had preceded it. The model discontinued in 2010, like all Harleys, attracted an army of fans, even if said army wasn’t large enough to lay siege to a Dunkin Donuts.

The Twin Cam’s reign ended in 2016 when it was replaced with the multi-valve dual-cooled Milwaukee-Eight, but as always, that’s another story.

With the Twin Cam, Harley-Davidson set out to build a bulletproof engine and one designed to handle future power upgrades. They succeeded in that quest and then some.

During its production run, the Twin Cam engine went from the 88ci to the 103ci high-performance engines of the Project Rushmore baggers. No other model in Harley-Davidson history has ever seen so many power upgrades from one engine platform.

| Year | Horse Power | Torque | |

| Knucklehead | 1936 | 36 | N/A |

| Panhead | 1948 | 50 | 65 ft lbs |

| Shovelhead | 1966 | 51 | 62 ft lbs |

| Evolution | 1984 | 56 | 69 ft lbs |

| Twin Cam 88 | 1999 | 62 | 82 ft lbs |

| Twin Cam 96 | 2007 | 68 | 92 ft lbs |

| Twin Cam 103 | 2012 | 74 | 100 ft lbs |

The post The Harley-Davidson Twin Cam: Bigger, Bolder and Better? appeared first on Old News Club.